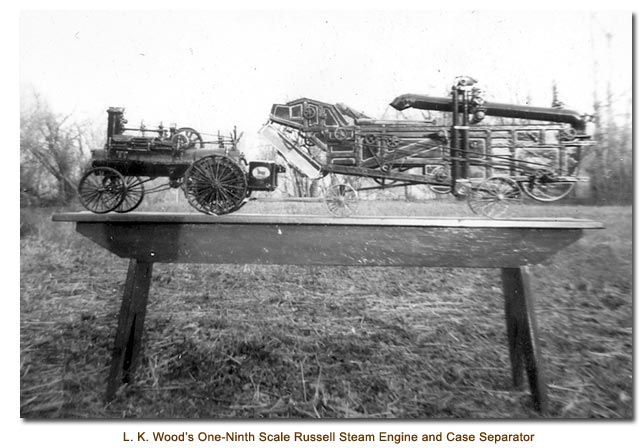

Mendon Resident Constructs Miniature Threshing Outfit

A miniature traction engine and “agitator” separator, which actually threshes grain under steam power, has been constructed from scrap wood and metal by L. K. Wood of Mendon. In constructing what he claims is the smallest working threshing rig in existence, Mr. Wood satisfied a lifelong interest in machinery, which began when he followed the crews from field to field during threshing time as a boy.

The miniatures were constructed to a one-ninth scale, patterned after the Russell traction engine and the Case separator, when they were the “last word” in grain harvesters fifty years ago. If they serve no other purpose their maker points out; the models may be valuable in preserving one stage of the historic development of the implements.

The entire threshing outfit weighs only forty-one pounds, twenty-seven and one-half for the power engine and thirteen and one-half for the separator. The engine is nineteen and one-half inches long, eight and one-half inches wide and eleven inches high. The separator is twenty-three and one-half inches in length over all, not including the straw carrier; nine and one-half inches in width and eleven in height, not including the carrier.

Mr. Wood selected his own “Old Betsy,” 1892 model, as a model for the traction engine. After working sixty, eight-hour days of spare time and time borrowed from other work; he tested the miniature at eighty pounds steam pressure. The main parts are wood patterns cast in brass and the flues are brass tubing from auto wreckage, but in good condition.

“After completing the engine,” the craftsman explains, “I started the separator, so depriving myself of every other pastime and infringing on my regular work, I spent fifty-three days at eight hours per day to complete the Case agitator model.” More bearings and more shafts made the latter a more technical job. Woodwork required carving to one-sixteenth of an inch thicknesses. Nails had to be drilled to make cylinder heads. All of the material was scrap from a junk pile, but trimmed exactly to scale. Mr. Wood then painted the two units exactly as in the original models.

“That satisfaction of seeing it run by steam and actually thresh wheat, other grains and seed, just like the big one, is well worth my tedious efforts.” He concludes.

![]()